The Guide to Concrete Crack Repair: Fillers and Patching Solutions

Understanding the Types of Concrete Cracks

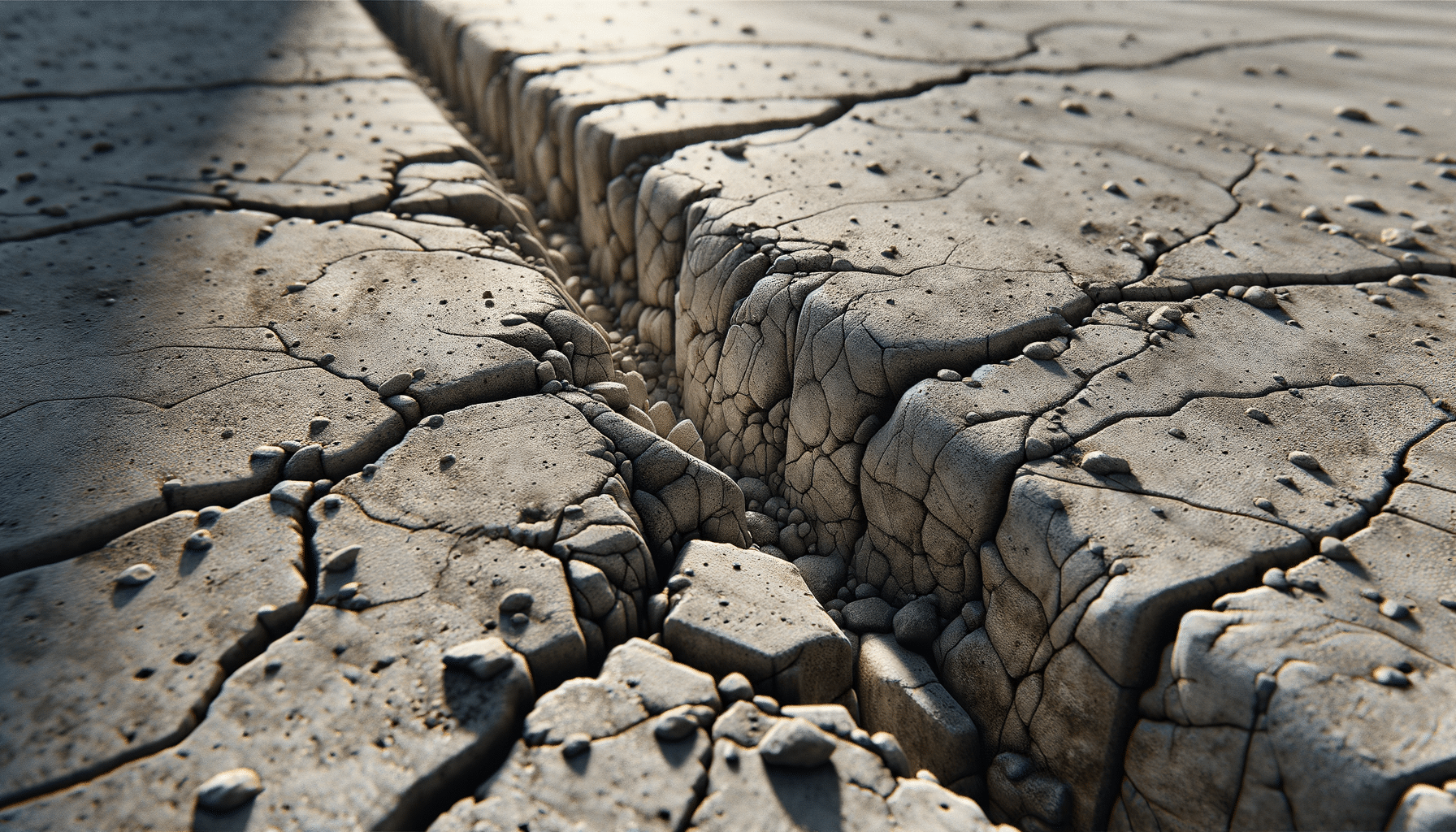

Concrete is a durable material, yet it is not immune to cracking. Understanding the different types of cracks is essential for selecting the appropriate repair method. Cracks can vary in width, depth, and cause, each requiring different approaches for repair. Common types include shrinkage cracks, settlement cracks, and structural cracks. Shrinkage cracks often appear during the curing process and are usually superficial. Settlement cracks occur when the ground beneath the concrete shifts or compacts. Structural cracks, however, are more severe and can indicate underlying issues with the concrete’s integrity.

Identifying the type of crack is the first step in the repair process. For instance, hairline cracks might not compromise the structural integrity but can allow water infiltration, leading to further damage. In contrast, wider or deeper cracks might suggest significant structural concerns. It is crucial to assess the crack’s width, depth, and pattern to determine the appropriate repair strategy. Tools like crack gauges or digital calipers can help measure and monitor crack development over time.

Understanding the cause and type of crack not only aids in choosing the right repair method but also helps prevent future occurrences. Preventive measures, such as proper concrete mix design, adequate curing, and controlling environmental conditions, are essential to minimize crack formation. By addressing the root cause, you can ensure long-lasting repairs and maintain the concrete’s strength and appearance.

Choosing the Right Repair Materials

The selection of repair materials is a critical step in the crack repair process. Various materials are available on the market, each designed for specific types of cracks and repair conditions. Common materials include epoxy injections, polyurethane foam, and cement-based fillers. Each material has its unique properties that make it suitable for certain applications.

Epoxy injections are often used for structural cracks as they provide a strong bond and restore the concrete’s original strength. They are ideal for indoor applications where aesthetics are a priority. Polyurethane foam, on the other hand, is flexible and can accommodate slight movements in the concrete, making it suitable for cracks caused by temperature fluctuations. Cement-based fillers are widely used for surface repairs and are excellent for patching non-structural cracks.

When selecting a repair material, consider factors such as the crack’s location, width, and environmental exposure. For outdoor repairs, materials that offer resistance to weathering and UV radiation are preferable. Additionally, consider the ease of application and the required curing time, especially if the repair needs to be completed quickly. By choosing the right materials, you ensure effective and long-lasting repairs that maintain the concrete’s integrity and appearance.

Step-by-Step Crack Repair Process

Repairing concrete cracks involves a systematic approach to ensure effectiveness and longevity. The process typically begins with cleaning the crack to remove any debris, dirt, or loose concrete. A clean surface allows for better adhesion of the repair material. Tools such as wire brushes or compressed air can be used to clear the crack thoroughly.

Once the crack is clean, the next step is to prepare the repair material. Depending on the chosen material, this might involve mixing components according to the manufacturer’s instructions. For instance, epoxy injections require precise mixing to achieve the desired properties. It is essential to follow the instructions carefully to ensure the material performs as expected.

After preparing the material, apply it to the crack using appropriate tools, such as a caulking gun for polyurethane foam or an injection kit for epoxy. Ensure the material fills the entire crack and extends slightly beyond the surface to allow for sanding or smoothing once cured. For larger cracks, consider using a backer rod to reduce the amount of material needed and provide additional support.

Finally, allow the repair material to cure according to the manufacturer’s guidelines. Curing times can vary significantly, so it is important to plan the repair process accordingly. Once cured, the repaired area can be sanded or finished to match the surrounding surface. A successful repair not only restores the concrete’s appearance but also prevents further damage and prolongs its lifespan.

Preventive Measures for Concrete Cracks

While repairing existing cracks is essential, preventing new ones is equally important. Implementing preventive measures can significantly reduce the likelihood of crack formation and maintain the concrete’s integrity. Proper mix design and curing practices are fundamental in preventing shrinkage cracks. Using the right water-to-cement ratio and incorporating admixtures can enhance the concrete’s properties and minimize cracking.

Controlling environmental conditions during the curing process is crucial. Protecting the concrete from extreme temperatures, wind, and moisture loss can prevent premature drying and shrinkage. Techniques such as using curing blankets or water sprays can help maintain optimal curing conditions.

Regular maintenance and inspection of concrete surfaces can also play a significant role in crack prevention. Early detection of minor cracks allows for timely repairs, preventing them from developing into more significant issues. Additionally, addressing underlying causes such as poor drainage or soil settlement can prevent cracks related to structural movement.

By adopting these preventive measures, you can enhance the durability and lifespan of your concrete surfaces, reducing the need for frequent repairs and ensuring a safe and aesthetically pleasing environment.

Common Misconceptions About Concrete Crack Repair

Concrete crack repair is often surrounded by misconceptions that can lead to improper practices and unsatisfactory results. One common myth is that all cracks are the same and can be repaired using the same method. As discussed, different types of cracks require different repair approaches, and using the wrong method can exacerbate the problem.

Another misconception is that small cracks do not need attention. Even minor cracks can allow moisture infiltration, leading to more extensive damage over time. Ignoring small cracks can result in costly repairs in the future. Regular inspection and timely repair of even the smallest cracks can prevent further complications.

Some believe that crack repair is a purely cosmetic procedure. While aesthetics are important, the primary goal of crack repair is to restore the concrete’s structural integrity. Choosing the right repair method and materials is crucial to achieving both aesthetic and functional outcomes.

Lastly, it is often assumed that DIY repair kits can solve all crack-related issues. While DIY kits can be effective for minor, non-structural cracks, more significant cracks or those affecting structural integrity require professional assessment and repair. Consulting with a professional ensures that the repair is done correctly and safely.

Understanding these misconceptions and approaching crack repair with the right knowledge and tools can lead to effective and long-lasting results, preserving the value and safety of your concrete structures.